Navajo-Gallup Water Supply Project

March 13, 2018

Providing Water Treatment Plant Safety

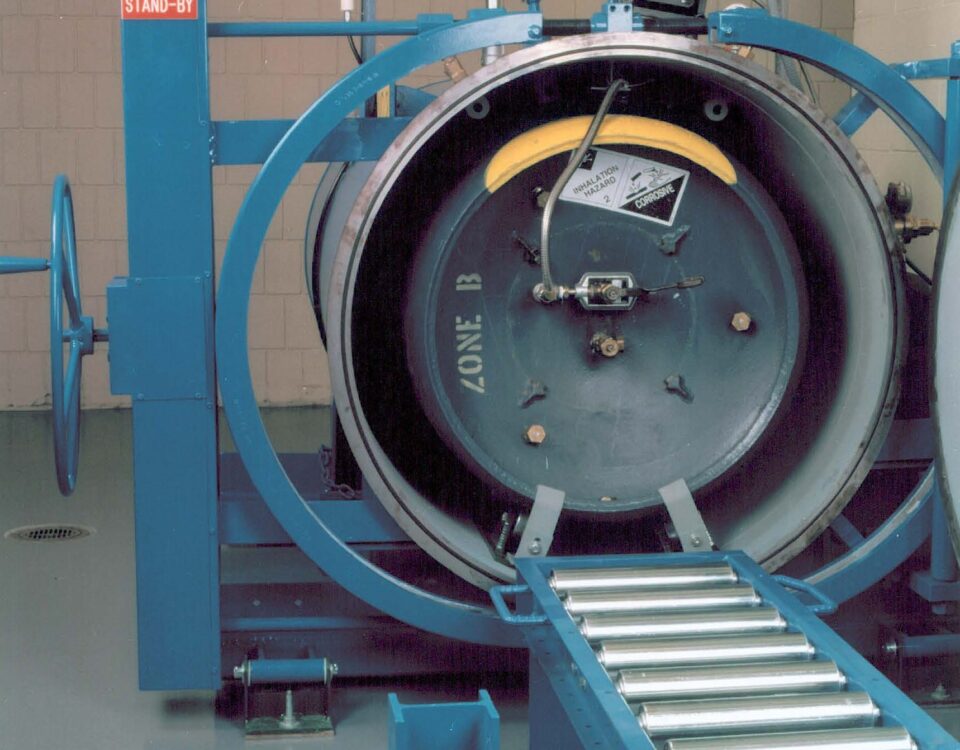

May 11, 2018ChlorTainer Delivers Cost-Effective Chlorine Gas Leak Prevention In Arizona

Eric Laurin, Associate/Director, CVL

Coe & Van Loo Consultants Inc. (CVL) in Phoenix, Arizona, has worked with ChlorTainer on a variety of water projects over the past decade for municipal and private water companies. Associate/Director Eric Laurin says there’s one very good reason for that: “There is great care in the design.”

When designing a gas chlorine disinfection system, the ChlorTainer approach is cost-effective compared to other methods.

Laurin finds that when designing a gas chlorine disinfection system, the ChlorTainer approach is cost-effective compared to other methods. Also, it allows the water system operator to meet all applicable fire, safety and regulatory agency requirements. In the case of a leak, he says, scrubbing systems require the use of chemicals, blowers and sophisticated controls to perform the cleanup, which is more labor-intensive and expensive in the long run. With ChlorTainer’s low maintenance requirements, simply changing an O-ring once in a while is about all that needs to be done to ensure safety.

A bigger challenge on water plant projects is convincing the public that using chlorine gas is safe. To Laurin, safety protocols, state and federal regulations, all work effectively to ensure safety. For chlorine gas to continue its success in treating water, “Education needs to continue so people are comfortable with it,” says Laurin. “Other methods are not as effective in delivering disinfection to the water system.”

These other techniques use chlorine in a powdered (tablets) or liquid form (bleach) and contain inert materials that reduce the amount of disinfection action when compared to gas chlorine. “You’re not getting the same bang for the buck,” says Laurin.