When it Comes to Chemical Safety,

be Proactive NOT Reactive!

ChlorTainer is the only proactive technology for preventing a chemical release.

If your organization uses gas or liquid chemicals, you know that they must be stored and handled with utmost care.

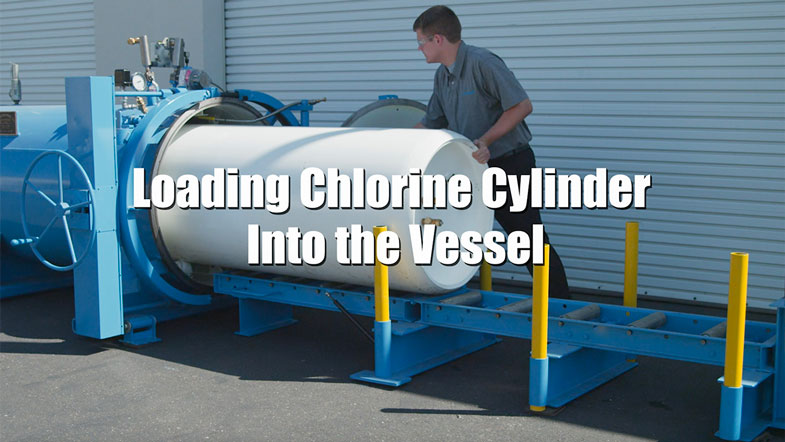

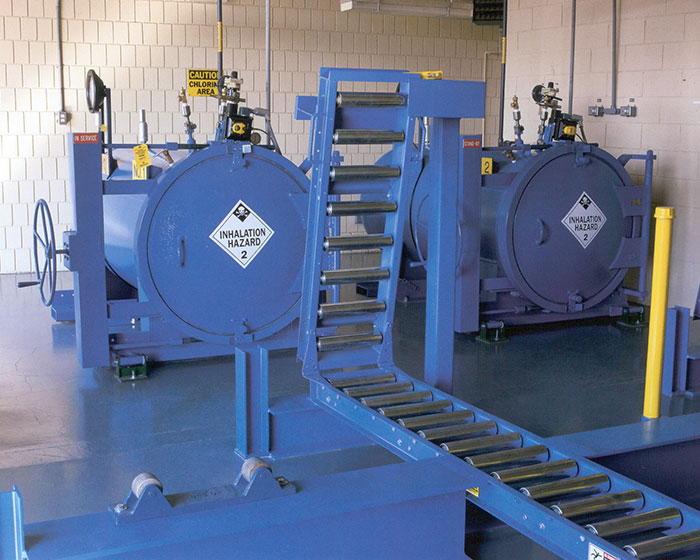

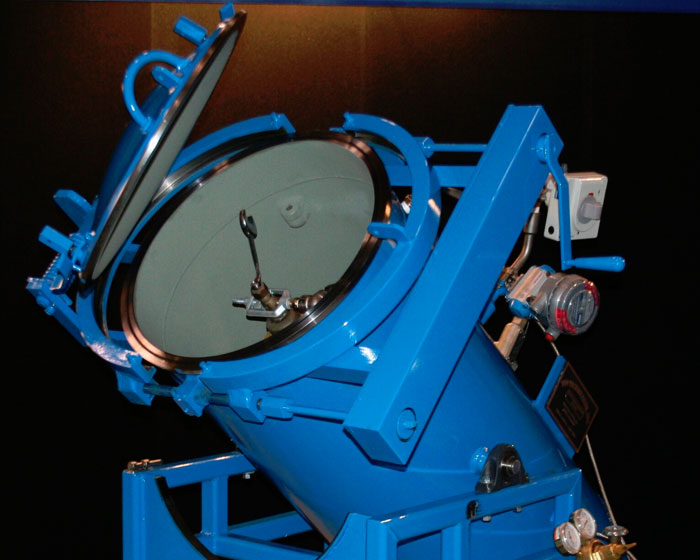

ChlorTainer is a high-pressure containment vessel into which a 1-ton or a 150-lb cylinder is processed. If the cylinder should leak, the gas or liquid is contained within the sealed vessel and processed at a normal rate.

ChlorTainer Introduction Video

ChlorTainer’s® annual maintenance takes about one hour and approximately $200.

ChlorTainer® enhances site security and provides fail-safe protection for plant operators.

ChlorTainer® is the only system that reduces the worst-case off-site release of toxic gas by 97%.

ChlorTainer® completely contains and processes a release at a normal rate.

With ChlorTainer’s® secondary containment system, no scrubber systems, fans, pumps, tanks, or mechanical systems are required.