Safety for Generations in Huntington Beach with ChlorTainer

October 13, 2022

ChlorTainer Install are “Straightforward as can be” in El Paso

February 9, 2023By Jamie Wright

The Challenges Faced by Modern WTP Professionals

WTP operators are professionals, parents, spouses, and community members who have a unique role in their community: they are responsible for providing safe water to every person, family, and business in their community.

As a WTP operator you are responsible for protecting, providing, and managing what is arguably the most valuable resource on the planet: WATER.

In the normal course of business, you face a complex decision-making process. You have multiple stakeholders – individuals, businesses, and regulators – who all have valid needs and interests pertaining to the provision of safe water for the community. However, stakeholder interests may diverge in how they would prioritize certain matters, such as balancing cost, operational complexity, and safety.

Furthermore, the ecosystems in which you work can vary widely. A water treatment professional may be supervising a plant within a growing community with an uncertain, but rising, demand for water over the coming years.

How can you plan infrastructure for this, meet the capital requirements, and operate the plant in the safest manner possible for the surrounding community?

Likewise, as a supervisor you may find yourself attempting to balance the ongoing operational expenses and maintenance of a legacy system while attempting to address emerging public perceptions about the safety of the WTP systems and chemicals used.

These modern challenges faced by WTP leadership are likely to grow as urban communities expand in population and density.

As communities grow and industry demand for water increases, the challenges faced by WTP operators will continue to require solutions that can simplify decision-making, mitigate risks, manage costs, and provide water long-term, affordable, water security to the communities they serve.

WTP Dilemma: A Risk-Benefit Balancing Act

Community and stakeholder perception about what is “best” for water treatment can vary widely and vacillate periodically. Stakeholders may perceive a certain modality as superior or inferior, high risk or safe, based upon limited information or a lack of awareness of the full suite of options available to the production of safe water.

In our modern era, the WTP processional may often feel stuck between a so-called “rock and hard place.” In many ways, the decision-making is not about choice, but rather feels like a trade among many vital factors.

With constraints and finite resources, the water treatment professional may face what could certainly feel like the impossible task: how do you choose between multiple crucial variables when ALL the variables are crucial?

How could you really make a compromise between:

- Capital cost efficiency – can we afford to build a new system?

- Operating cost efficiency – how can we make operating costs sustainable?

- Scalability and flexibility – how can our system adapt to growth and change?

- Security and protection – how can we protect our system from external threats?

- Safety for workers and community – how can we best protect our people?

- Efficacy and durability – what treatment methodology has the best track record?

For example, WTP industry experts generally agree that chlorine gas is the most efficient, cost-effective, and safe modality to treat drinking water. Chlorine gas is known to be the most cost-effective method to deliver sanitizing chlorine into a WT facility; however, as population density around WTP facilities increases, stakeholder concern about the safety and viability of chlorine gas as the benchmark solution for water treatment may emerge.

WTP operators increasingly find themselves having to weigh both the real and perceived risk of a chlorine gas leak and its potential impact on a community against the capital, infrastructure, and short and long-term operational costs associated with converting a gas treatment facility. Conversion away from gas treatment is both capital and operationally intensive; and, over the long-term may significantly affect maintenance and supply costs related to water treatment.

Ideally, a WTP could continue to use chlorine gas, or even convert to chlorine gas for its improved sanitization efficiency and lower operational expense profile and simultaneously overcome the safety risks associated with the use of chlorine gas.

“Chlorine Containment” Can Eliminate a Difficult Trade-Off

Current chlorine gas system operators may face pressure to address the safety concerns, both real and perceived, related to the use of gas.

But what if a chlorine gas system could be cost-effectively modified to enhance its safety profile for workers and the surrounding community?

What if a single addition to your chlorine gas system could simultaneously provide added protection from outside threats?

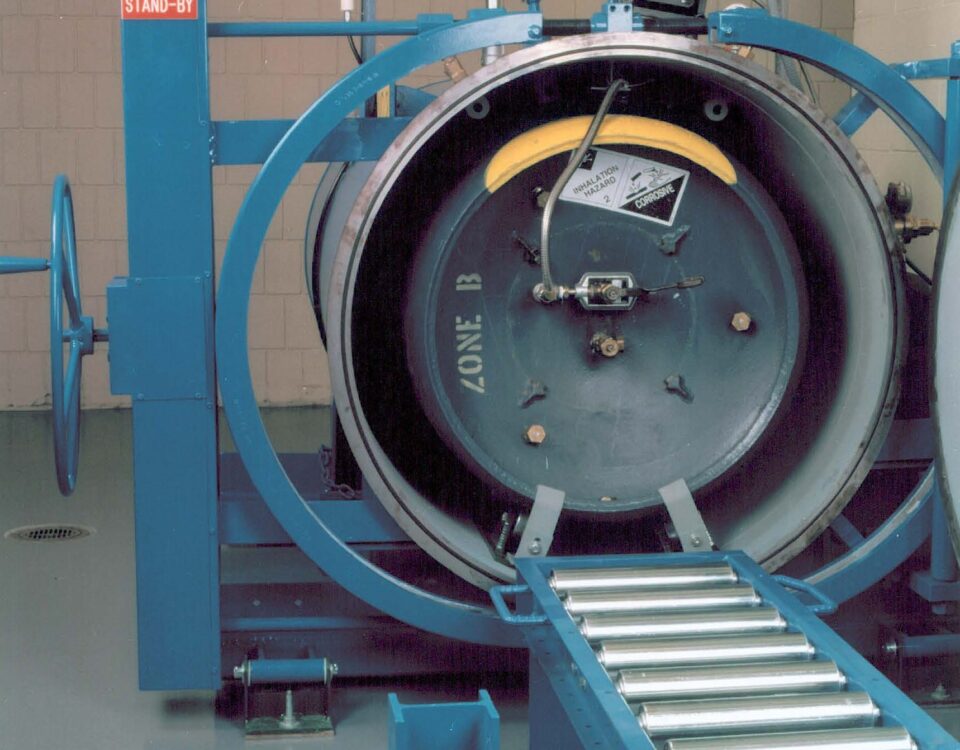

Marketed under the brand name ChlorTainer® , TGO Technologies based in Santa Rosa, CA manufactures a high-pressure containment vessel into which a one-ton or a 150-pound chlorine gas container is inserted using a custom-designed roller system. ChlorTainer® employs a user-friendly design that adapts easily to current chlorine gas systems.

The vessel processes chlorine though a vacuum regulator connected to a failsafe actuator. If the container should leak, ChlorTainer® encapsulates the chlorine gas and continues to process at a normal flow rate. There is no interruption of service. The system allows use of all the chlorine gas and does not generate hazardous waste.

ChlorTainer® eliminates the need for a scrubber or emergency response team and has safety features that function during a loss of power without the need for a backup electrical generator.

ChlorTainer® : Making Chlorine Gas Safe, Secure, and Cost-Efficient

Water treatment plant operators and chemical professionals looking for alternatives to the use of unprotected chlorine gas systems should carefully weigh the risks and benefits of ongoing use of chlorine gas. Capital, operational, and maintenance costs related to converting an entire system away from chlorine gas may not prove to be beneficial when a chlorine gas leak can be PREVENTED by use of ChlorTainer® containment vessels.

It may be concluded that the safety enhancements offered by ChlorTainer® can allow for the ongoing use of a current chlorine gas system and provide safety that is superior to even non-chlorine gas alternatives.

Enhancing a chlorine gas WTP with the use of ChlorTainer® brings multiple benefits:

- Uninterrupted benefits of a chlorine gas WTP

- Normal WT plant operational process (generally within a few hours, ChlorTainer® installs directly into current gas systems).

- Ongoing sanitization benefits of chlorine gas.

- Ongoing cost efficiencies of chlorine gas (product, maintenance, and storage).

- Safety benefits of adding ChlorTainer® :

- ChlorTainer® is a nearly indestructible containment structure that protects chlorine gas tanks while they are being used during normal operational processes.

- ChlorTainer® systems provide safety containment not only for chlorine gas, but for

anhydrous ammonia and sulfur dioxide as well. - Built to ASME code and can easily withstand the maximum pressure produced by a failed chemical container, ChlorTainer® is the only system that reduces the worst-case off-site release of toxic gas by 97%.

- ChlorTainer® provides the safest and most reliable technology available, providing fail-safe protection for operators and the surrounding community.

- Seismically balanced and secured to a foundation, ChlorTainer® provides protection against intentional or unintentional damage and weather-related environmental issues like high wind, building damage, earthquake, etc.

- ChlorTainer® is a sealed, secure, and lockable vessel that will contain an accidental chlorine gas leak while recycling and using any lost chlorine gas, so no hazardous waste is generated.

- Pressure and chemical-sensitive valves automatically close in the event of a downstream chlorine gas leak, even during the loss of electrical power. WTP staff can be quickly trained to operate and maintain a ChlorTainer® vessel.

- Expended chlorine gas containers are easily and ergonomically swapped into the

ChlorTainer® vessel, protecting employees from accidental exposure to chlorine gas and injury from lifting and moving chlorine gas tanks.

ChlorTainer® systems are being used at municipal water sites nationwide and internationally to provide protection to operators and their surrounding community. ChlorTainer’s long-lasting design allows water managers to continue benefiting from their chlorine gas investment while achieving a new standard of safety.