ChlorTainer Install are “Straightforward as can be” in El Paso

February 9, 2023

City’s Water Utilities Capital Projects Manager Reports Long Term Safety Enhancement from Special Secondary Containment Vessels for Chlorine Gas Cylinders

May 4, 2023In the harbor town of Ludington, a state-of-the-art wastewater treatment plant (WWTP) now features a ChlorTainer containment vessel. Plant superintendent, Chris Cossette, helped make the renovation possible, working closely with Matt Fuller.

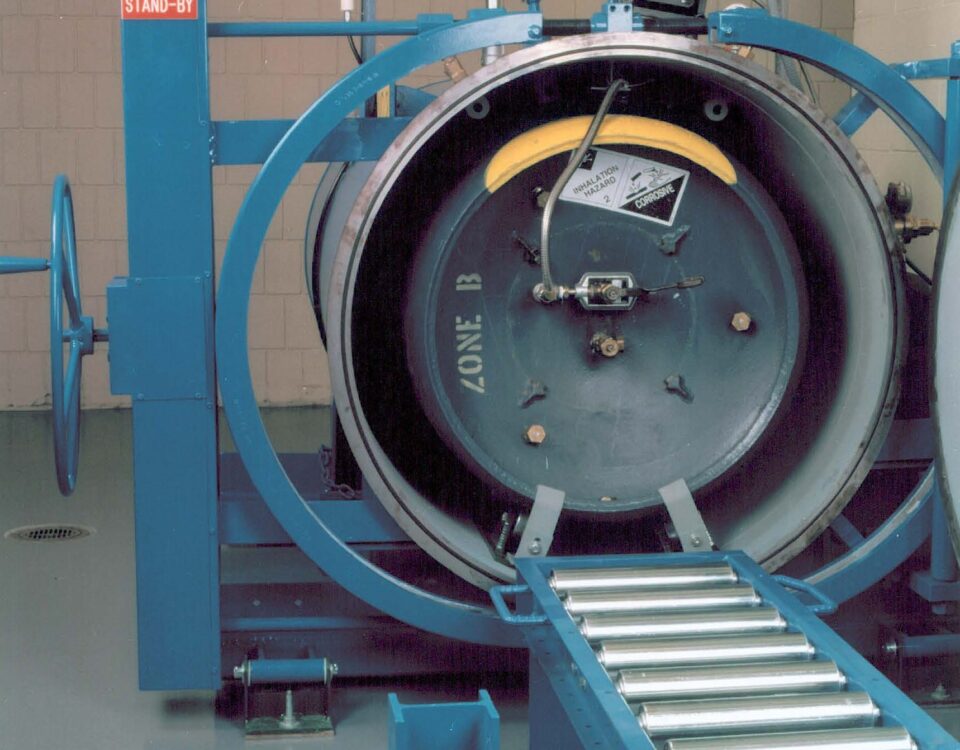

Fuller is a mechanical contractor with Franklin Holwerda Company. Cossette and Fuller helped transition the previous wastewater system to a site that uses a single 150-pound secondary containment vessel.

ChlorTainer Installation Took One Week, Fuller Recalls

Matt Fuller was a foreman with the Franklin Holwerda Company as the mechanical contractor for the project. In general, most of Fuller’s work involves helping municipalities.

Renovations for the large-scale renovation in Ludington took years, but the ChlorTainer installation was quick. “That part took about a week for three of our guys,” Fuller recalls.

Before the ChlorTainer installation, renovations at the plant began as early as 2019. The WWTP was in transition from a plant with an aerated lagoon to a plant featuring an earthen base and activated sludge. In 2021, one of the additions was the chlorine containment tank for the disinfection, since, as Cossette explains, “with activated sludge, you can’t chlorinate in your clarifiers.”

“We had some troubleshooting to do,” Fuller shares,” and the electricians were involved for a bit. That’s why it took a week.”

With two pipefitters and one electrician, they completed the installation.

ChlorTainer Provided Fuller with Contacts and Subcontractors

During the installation in Ludington, Matt Fuller appreciated the list ChlorTainer provided with contacts for subcontractors. After contacting them, Fuller says his team had “plenty of help to get us heading in the right direction.”

Fuller also worked one-on-one with Rudy at ChlorTainer, who helped Fuller assess the installation details. “I probably spent 6-8 hours on the phone or going through the details with ChlorTainer,” he shares.

The tricky part for installation involved a leaking regulator. “We had a couple of site visits after the install, where we had to troubleshoot that leak. Other than that, everything worked as it should have.”

Overall, Installation of ChlorTainer Vessel was “Straightforward and Easy”

After collecting additional information, Fuller felt that his team could complete the installation. “The electricians had a few complications trying to figure out the controls with everything because they weren’t familiar with it,” he explains. “But other than that, it was pretty straightforward and easy to install.”

No other wastewater treatment plant in Michigan had installed a ChlorTainer containment vessel; there was a learning curve for everyone. The benefits of ChlorTainer containment vessels made the installation worth it.

Explore the interactive field site map to learn where ChlorTainer vessels are making it safer to store gas or liquid chemicals. If your organization uses gas or liquid chemicals, learn more about our safe and reliable high-pressure secondary containment vessels at www.chlortainer.com or call us at (800) 543-6603.