Delivering Cutting-Edge Chemical Storage Solutions to the U.S. Army: A Testament to Safety and Innovation

May 30, 2024

Inventor of Unique, Proactive, Secondary Containment Vessels for Preventing Hazardous Gas Release from Cylinders and Ton-Containers Adds New Product for Preventing Release from Bulk Storage Tanks

August 14, 2025Water Production Supervisor Credits Secondary Containment Vessels for Chlorine Gas Ton-Containers for Help with Risk Management Plan Audits, and Ongoing Plan Management

Also Notes Benefits vs. Scrubbers, and Enhanced Community and Storm Safety

The water production supervisor for the City of Lake Charles, LA has credited long-term use of secondary containment vessels for chlorine gas ton containers with assistance in risk management plan (RMP) audits, as well as ongoing Plan management. He also notes benefits gained from their use as an alternative to scrubbers, and enhanced community and storm safety.

Efron Simon said the innovative technology has been in use at several of his six current facilities, starting around 2016. With a seventh plant coming online soon, his total output will be an average of 20 MGD, serving a population of about 90,000, via about 33,000 connections. An eighth plant is in the planning stage.

“We haven’t had any problems with gas releases, but it’s good to know if there are any, they are not only captured in the secondary vessels, but are put back into disinfection production,” he said. “When an RMP inspection team from the state Dept. of Environmental Quality (DEQ) came in recently, they were rather impressed.”

“One of the questions they asked was why the secondary vessels weren’t at all our facilities. I said, well, they could be if y’all could loan me the money to purchase them all. Once they went through and had seen them and everything, one of their recommendations was pretty much, that it’s a recommended product to have at your facility.”

Simon had explained that “if it’s a weekend, I don’t have full crews like Monday through Friday. But if an operator on a weekend found out that a gas container erupted, he could continue to let the system operate. And then Monday they can all go in and take care of the problem. So it becomes an urgency instead of an emergency.”

The water production supervisor for the City of Lake Charles, LA has credited long-term use of secondary containment vessels for chlorine gas ton containers with assistance in risk management plan (RMP) audits, as well as ongoing Plan management. He also notes benefits gained from their use as an alternative to scrubbers, and enhanced community and storm safety.

“With the sensor system tied in and having alerted us, now when we do go in, we don’t need a full hazmat gear situation for an operator; the proper gear now is just a face shield when we open the door of the containment vessel. The inspection team was also very impressed because they saw no more scrubber system. They understood that instead of a leak from scrubber containment, there was capture by the vessel, and I can keep pulling from the ton container until it’s empty, and then go through the normal ton-container changeout.”

Regarding the benefits of secondary containment vessel deployments compared to scrubbers, Simon recalled a prior inspection, “where the scrubber system we had was not operative. And so it was a deficiency that we had on our system that we had to address. When you use the secondary vessel containment system, you find how employee friendly it is and how much better it is than having to have to deal with a scrubber system or any other system.”

Secondary containment vessels for chlorine gas cylinders and ton containers have been installed as reliable, lower-maintenance, enhanced leak safety alternative to wet and dry scrubber systems.

“If you have a scrubber system, the chemical you have to use in that scrubber system, the mechanical parts that have to move to keep that scrubber system going, how often you have to do motor maintenance, pump maintenance, gear maintenance. What is your cost? When you come down and look at the long term cost of what it costs you to do this in man hours, and then the man hours in comparison to the secondary vessels, you find that in the long run, it’s cheaper to have them than it is to have a scrubber system.”

“There’s no mechanical movable parts; there’s no chemical that has to be regenerated; there’s no constant stirring up the chemical. With this alternative, you can just spend two man hours doing the seal and greasing the threads, and making sure that that’s good; the seals are good. And then I have a change out system where I take it off and send it into the shop, and put out another one.”

“In two years, in my man hours and all that, I have recouped what I would have spent on that system itself. And then in the long run, you get what they call a return on your investment down the line in man hours.”

Regarding storm safety, Simon noted his facilities were only about 30 miles from the ocean, so they have routine precautionary measures in place.

“It helps that we have our chlorine ton containers inside containment vessels that are sealed. It makes it easier for us to see that they are secured. Our ultimate plan is to have them put inside of a building, but for now we just take our rotometers off.”

Regarding community safety, Simon noted “one site where the vessels are outside, and there is a school across the street. Having the containment vessels system in place definitely makes me feel a whole lot better. Otherwise, you might have to deal with emergency response; deal with DEQ.”

A failsafe valve ties into the chlorine leak detection sensor, so that in the event of an external release, a nitrogen and electric-powered failsafe valve will close, stopping it completely. Any leak or release of chlorine gas from the vacuum line downstream of a vacuum regulator (mounted on top of vessels) will lose the vacuum condition, and cause the vacuum regulator to close, stopping the flow of chlorine gas to the vacuum line.

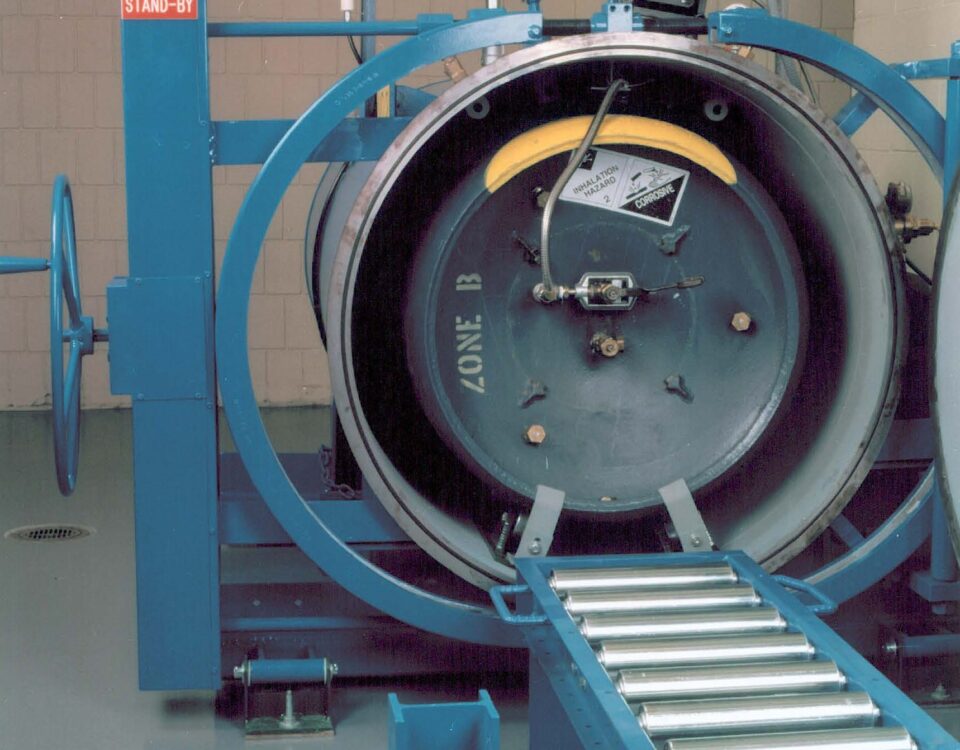

Original deployment of the secondary containment vessels required working with the manufacturer to situate them without putting them “in doorways, and entry and exit doors.”

The manufacturer also provided comprehensive assistance with helping operators establish new procedures for handling the chlorine ton-containers, and work with them to resolve any difficulties. For example, it helped to establish the use of motorized doors for the vessels.

“Once they got those issues resolved, it became something that they don’t complain about.,” Simon recalled. “Then we just had to focus on the proper times for the upkeep of maintenance. After having them for a few years and working out the kinks, working out the concerns that we had, we feel pretty good with them.”

“I call those minor technicalities, nothing that’s major to really cause us any major issue. I like their customer service. Because if you have an issue and you reach out, there’s an email or there’s a phone call that comes back to you to help you address any issues that you have, and their team has also visited.”

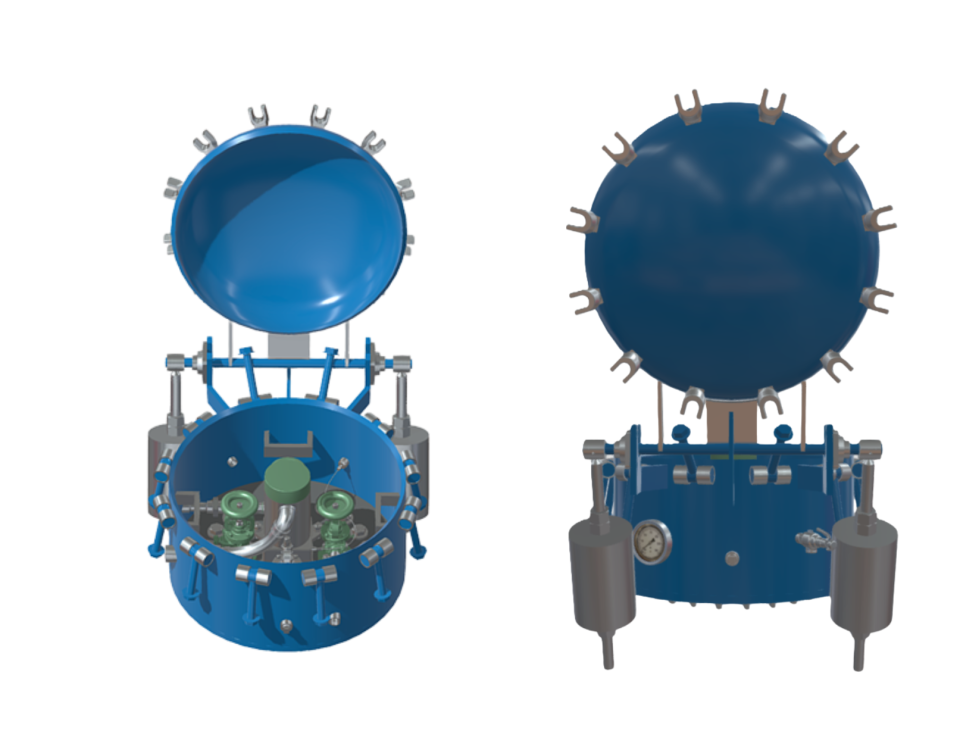

The special secondary containment vessels for chlorine gas one-ton containers, which are also available for 150-lb. cylinders, are manufactured by ChlorTainer/TGO Technologies, Inc. of Santa Rosa, CA. A double one-ton unit is also available. The vessels are ASME-rated pressure tanks, and any leaks are recycled to the injection system at a normal flow rate. A failsafe valve ties into the chlorine leak detection sensor, so that in the event of an external release, the nitrogen failsafe valve will close, stopping it completely.

The vessels’ life expectancy is stated as no less than 100 years, given proper maintenance. This features annually changing out the Viton O-ring on the door, which takes about half an hour of time and approximately $200.